President of Ukraine International Airlines (UIA) Yevhen Dykhne does not see any reasons for airlines to raise airfare at the initial stage of lockdown ending.

During the press conference on Saturday, June 13, the video of which is available on the page of Boryspil International Airport, he said that all airlines today have excess resources, and at the same time very low demand is expected for their services, which will be compensated by all possible means.

“Therefore, it is absolutely logical that all instruments, including low prices, will be included in the fight against excess resources between companies for low demand and low passenger numbers. Due to this, insinuating that the additional costs of airlines and airports will somehow affect the airfare, in my opinion, is not justified. Today, the airfare is defined by the market’s supply-demand situation. Thus, I think that aviation will start operation from very low prices, affordable flights at a loss,” Dykhne said.

He also said that UIA communicates with all passengers who bought tickets for the airline’s flights, considering options for transferring flight dates, compensation using a voucher, or refund.

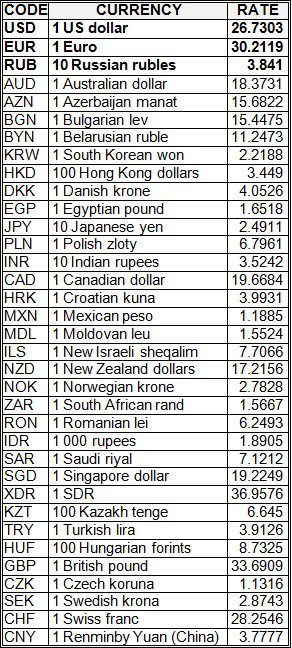

National bank of Ukraine’s official rates as of 15/06/20

Source: National Bank of Ukraine

Moody’s Investors Service has upgraded the Government of Ukraine’s long-term issuer and senior unsecured ratings to B3 from Caa1. The outlook on the ratings is stable, Moody’s said in a report.

According to the report, the main driver of the decision to upgrade the ratings to B3 is the easing of Ukraine’s near-term funding challenges and the safeguards afforded to recent improvements in its external vulnerability as a result of the announced new financing programme with the International Monetary Fund (IMF)

The decision to upgrade the ratings also reflects Moody’s expectation that the new IMF programme will help anchor the reform progress achieved in recent years, Moody’s said.

Head of the Specialized Anti-Corruption Prosecutor’s Office (SAPO) Nazar Kholodnytsky has said that former U.S. Vice President Joe Biden and his son Hunter are not involved in the case of offering a bribe to the top officials of anti-corruption bodies for closing the episode, which involves former ecology minister Mykola Zlochevsky.

During a briefing on Saturday, asked about whether Hunter Biden is involved in the bribe criminal proceedings, since he is directly connected with Zlochevsky and Burisma Holdings, Kholodnytsky said: “Let’s put an end to this once and for all. Biden Jr. and Biden Sr. do not appear in this particular proceeding.”

Director of the National Anti-Corruption Bureau (NABU) Artem Sytnyk said that the bribe was offered for closing the episode regarding the stabilization loan, which was issued by the National Bank to Real Bank associated with Serhiy Kurchenko.

“Let’s not turn this matter into a political subtext,” Sytnyk said.

The Ukrainian government has made several decisions changing the entry requirements for foreign citizens and stateless persons, the country’s State Border Guard Service said on Saturday. Under the government decree No. 477, approved on June 12, the temporary entry ban for foreigners is no longer effective.

Another decree, No. 480, of June 12, requires foreigners to have a relevant insurance policy and those arriving from countries with high number of coronavirus infections to undergo observation.

For the duration of the quarantine, foreigners and stateless persons (except permanent residents, refugees, or persons seeking additional protection) will be banned from entry if they do not have an insurance policy (certificate) to cover the costs relating to COVID-19 treatment and observation, the decree said.

Arriving from, or being a citizen of, a country with a high number of COVID-19 cases shall be ground for observation, the government said.

“To ensure the transportation of persons from state border checkpoints to observation facilities, the government has compelled regional and Kyiv city state administrations,” the agency said.

At the same time, a citizen (subject) of a country with a high number of COVID-19 infections, who has not been in that country in the previous 14 days, foreign diplomats and consular officials, representatives from accredited international missions and organizations and their family members, drivers and crew members of cargo transport vehicles, air, sea and river crews, members of train and locomotive brigades, participants in an external independent audit (with one accompanying person each), will not be required to undergo observation, unless there is a reason to believe that they have been in contact with a COVID-19 patient.

Also exempt from observation will be those who agree to self-isolate using an act-at-home electronic service.

A country is considered to have a high number of COVID-19 cases if it had at least 40 active cases per 100,000 population.

A list of such countries will be updated and submitted by the State Border Guard Service to the Foreign Ministry every three days.

Therefore, foreign citizens and stateless persons may cross the Ukrainian border from the effective date of the Decrees No. 477 and No. 480, providing they have legal grounds for entry, as stipulated in the Ukrainian border control law, and observe sanitary epidemiological rules.