In January-September of this year, the Zaporizhstal metallurgical plant increased its rolled steel production by 14.1% compared to the same period last year, from 1.829 million tons to 2.0866 million tons.

According to the plant’s press release, steel production for the period amounted to 2 million 385.2 thousand tons (in January-September 2024 – 2 million 176.7 thousand tons), and 2 million 642.6 thousand tons of pig iron (2 million 297.5 thousand tons).

In September, Zaporizhstal produced 303.4 thousand tons of pig iron, 279.8 thousand tons of steel, and 247.3 thousand tons of rolled products, compared to 309 thousand tons of pig iron, 264 thousand tons of steel, and 231.2 thousand tons of rolled products in the previous month.

As reported, in 2024, Zaporizhstal increased its rolled steel output by 18.1% compared to 2023, to 2 million 426.7 thousand tons from 2 million 54.7 thousand tons, and steel output by 17.2%, to 2 million 890.8 thousand tons, and pig iron by 14.2%, to 3 million 106.3 thousand tons.

In 2023, Zaporizhstal increased its rolled steel production by 57.2% compared to 2022, to 2 million 54.7 thousand tons, steel by 65.4%, to 2 million 466.9 thousand tons, and pig iron by 35.3%, to 2 million 718.9 thousand tons.

Zaporizhstal is one of Ukraine’s largest industrial enterprises, whose products are in high demand among consumers both in the domestic market and in many countries around the world.

Zaporizhstal is a joint venture of the Metinvest Group, whose main shareholders are System Capital Management (71.24%) and Smart Steel Limited (23.76%). Metinvest Holding LLC is the managing company of the Metinvest Group.

In January-August of this year, the Zaporizhstal steel plant in Zaporizhia increased its rolled steel output by 11.9% compared to the same period last year, from 1 million 644.4 thousand tons to 1 million 839.3 thousand tons.

According to the plant’s press release on Wednesday, steel production for the period amounted to 2 million 105.5 thousand tons (in January-August 2024 – 1 million 973.7 thousand tons), and 2 million 339.2 thousand tons of pig iron (2.049 million tons).

In August, Zaporizhstal produced 310.8 thousand tons of pig iron, 277.3 thousand tons of steel, shipped 245.9 thousand tons of rolled products, compared to 309 thousand tons of pig iron, 264 thousand tons of steel, and 231.2 thousand tons of rolled products in the previous month.

As reported, in 2024, Zaporizhstal increased its rolled steel output by 18.1% compared to 2023, to 2 million 426.7 thousand tons from 2 million 54.7 thousand tons, and steel output by 17.2%, to 2 million 890.8 thousand tons, and pig iron by 14.2%, to 3 million 106.3 thousand tons.

In 2023, Zaporizhstal increased its rolled steel production by 57.2% compared to 2022, to 2 million 54.7 thousand tons, steel by 65.4%, to 2 million 466.9 thousand tons, and pig iron by 35.3%, to 2 million 718.9 thousand tons.

Zaporizhstal is one of Ukraine’s largest industrial enterprises, whose products are in high demand among consumers both in the domestic market and in many countries around the world.

Zaporizhstal is a joint venture of the Metinvest Group, whose main shareholders are System Capital Management (71.24%) and Smart Steel Limited (23.76%). Metinvest Holding LLC is the managing company of the Metinvest Group.

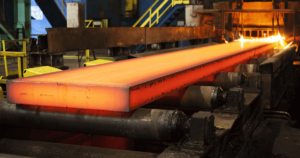

Zaporizhstal, a steel company in Zaporizhia, is investing over UAH 135 million in major repairs to heating wells in its hot rolling shop.

According to a press release issued by the plant on Thursday, the company is continuing comprehensive capital repairs of three groups of heating wells (four wells in each group) in the slab department of the hot rolling mill in accordance with its annual capital investment program. The total investment exceeds UAH 135 million.

“Today, Zaporizhstal is operating at only 75% of its capacity, but we are implementing the program for the maintenance and repair of production equipment at 100%. In particular, a major upgrade of the heating wells, which are an important link in the hot rolling process at Zaporizhstal, is currently underway. The quality of finished metal products, the mechanical properties of rolled products, and their compliance with standards and customer requirements depend on the stability of the temperature regime and the uniformity of heating of billets in the wells,” said Acting CEO Taras Shevchenko.

According to him, in addition to specialists from the engineering service, automation department, and central electrical engineering laboratory, specialists from the contracting organizations Etalonbudservis and MSC Prime are also involved in the overhaul. As part of the overhaul, worn refractories will be dismantled and replaced with new linings, in particular those manufactured by Zaporizhzhya Refractories. The total weight of refractory bricks and shotcrete mixture is more than 2,200 tons.

In addition, mechanical and power equipment, communications, and shut-off valves will be upgraded, about 900 tons of metal structures will be replaced, and hydraulic devices, automation, temperature sensors, etc. will be repaired and replaced.

Heating wells provide thermal preparation of ingots weighing up to 16 tons before rolling into slabs and further into thin rolled products. The overhaul of this equipment complex will significantly improve its reliability, energy efficiency, and minimize the risk of unplanned technological stoppages.

It is specified that this year Zaporizhstal will carry out a complex overhaul of key units of the thermal power plant – boiler unit No. 5, turbine generator No. 1, and turbo compressor unit No. 7. The plant will allocate about UAH 75 million for these purposes. Overall, despite the difficult economic situation, the capital investment budget for 2025 has been increased to UAH 1.1 billion.

Zaporizhstal is one of Ukraine’s largest industrial enterprises, whose products are in high demand among consumers both on the domestic market and in many countries around the world.

Zaporizhstal is a joint venture of the Metinvest Group, whose main shareholders are System Capital Management (71.24%) and Smart Steel Limited (23.76%). Metinvest Holding LLC is the managing company of the Metinvest Group.

In January-June this year, Zaporizhstal Iron and Steel Works increased its rolled steel output by 6.8% year-on-year to 1 million 317.5 thousand tons from 1 million 233.5 thousand tons.

According to the plant’s press release on Tuesday, steel production for the period amounted to 1 million 564.1 thousand tons (1 million 486.4 thousand tons in January-June 2014), and pig iron production amounted to 1 million 719.4 thousand tons (1 million 527.3 thousand tons).

In June, Zaporizhstal produced 292.5 thousand tons of iron, 267.5 thousand tons of steel, and 220.4 thousand tons of rolled products.

As reported, in 2024, Zaporizhstal increased its rolled steel output by 18.1% compared to 2023 – to 2 million 426.7 thousand tons from 2 million 54.7 thousand tons, steel – by 17.2% to 2 million 890.8 thousand tons, pig iron – by 14.2% to 3 million 106.3 thousand tons.

“In 2023, Zaporizhstal increased its rolled steel output by 57.2% compared to 2022, to 2 million 54.7 thousand tons, steel by 65.4%, to 2 million 466.9 thousand tons, and pig iron by 35.3%, to 2 million 718.9 thousand tons.

“Zaporizhstal is one of the largest industrial enterprises in Ukraine, whose products are in great demand among consumers both in the domestic market and in many countries of the world.

“Zaporizhstal is in the process of integration into Metinvest Group, whose major shareholders are System Capital Management (71.24%) and Smart Holding Group (23.76%).

Metinvest Holding LLC is the management company of Metinvest Group.

The Zaporizhstal steelworks in Zaporizhia has begun a series of major repairs to key energy equipment.

According to its annual capital investment program, Zaporizhstal will repair key units of the thermal power plant this year, allocating approximately 75 million hryvnias for this purpose.

“The thermal power plant is responsible for the production of three key types of energy resources – steam, blast air, and electricity – and supplies them to the plant’s divisions, ensuring the continuity of the production process at the sintering plant, blast furnace, rolling and other main and auxiliary shops. The overhaul will improve the reliability and uptime of both individual units and the entire energy complex of Zaporizhstal,” said Taras Shevchenko, acting CEO of the company.

It is specified that the plant will repair the power equipment in stages, as the work will be carried out while production continues, maintaining planned production volumes.

Zaporizhstal has already begun a large-scale overhaul of boiler unit No. 5, which is scheduled to be carried out every few years and will last about 100 days. Next in line is turbo compressor unit No. 7, with all planned work to be completed within 80 days. In the fall, major repairs will begin on turbine generator No. 1, which will last 45 days. Preparatory work is currently underway.

The major repairs will be carried out by the company’s own engineering service with the involvement of contractors Inventum Ukraine and Intel Energo.

The company notes that despite the difficult economic situation, Zaporizhstal is gradually increasing its capital investments in production during the war: in 2022, investments amounted to UAH 500 million, in 2023 – UAH 750 million, and in 2024 – UAH 938 million. The capital investment budget for 2025 is planned at UAH 1.1 billion.

Zaporizhstal is a joint venture of the Metinvest Group, whose main shareholders are System Capital Management (71.24%) and Smart Steel Limited (23.76%).