Additive manufacturing reduces production and time costs while meeting the highest safety standards in the industry

CRANBURY TOWNSHIP, Pennsylvania, March 2024 – Westinghouse Electric recently achieved a new milestone by producing its 1,000th fuel plate using additive manufacturing (3D printing). This is an important achievement for the industry: the first time additive manufacturing has been used to produce safety-related components that have entered mass production.

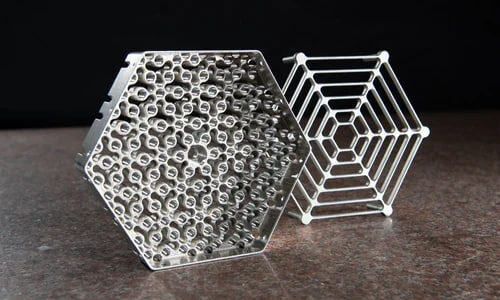

A fuel assembly component manufactured using additive manufacturing

The current additive manufacturing plates are installed in VVER-440 fuel assemblies, allowing for redesign of the lower part of the assemblies. This ensures their more reliable operation.

“This achievement demonstrates the development of additive manufacturing from prototyping to full-scale production. In addition, it creates concrete value for our customers,” said Lou Martinez Sancho, chief technology officer and executive vice president of research and innovation at Westinghouse. He also added: “This is yet another leading-edge achievement for Westinghouse in additive manufacturing technology, supporting our strategic plans to improve safety, efficiency, sustainability and energy security.”

The move continues Westinghouse’s leadership in using additive manufacturing in the nuclear industry to achieve cost and time reductions and to deliver advanced energy production solutions. In 2015, the company conducted the first-ever radiation exposure study of nuclear reactor components manufactured using additive manufacturing. In 2020, Westinghouse installed the first safety-related component made using additive manufacturing, a plugging device, in an active commercial reactor.

###

The Westinghouse Electric Company is shaping the future of carbon-free energy by providing safe, innovative nuclear technologies to utilities around the world. Westinghouse installed the world’s first commercial water-water reactor in 1957, and the company’s technology powers nearly half of the world’s active nuclear power plants. More than 135 years of innovation make Westinghouse the partner of choice for advanced technologies spanning the entire nuclear energy lifecycle. For more information, visit www.westinghousenuclear.com and follow us on Facebook, LinkedIn and Twitter.