ArcelorMittal Kryvyi Rih (Kryvyi Rih Iron and Steel Works, Dnipro region) plans to install electric generators at industrial site No. 1 of the Underground Mining Department of the Mining Department of Kryvyi Rih, according to materials obtained by Interfax-Ukraine.

According to them, it is planned to obtain a permit for emissions of pollutants into the atmosphere by stationary sources of this industrial site.

It is noted that new sources of emissions from the operation of generators that are planned to be used to provide electricity to consumers in the event of a power outage are not subject to environmental impact assessment.

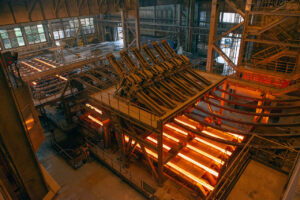

“ArcelorMittal Kryvyi Rih is the largest producer of rolled steel in Ukraine. It specializes in long products, including rebar and wire rod. The company has a full production cycle and its production capacities are designed to produce over 6 million tons of steel, over 5 million tons of rolled products and over 5.5 million tons of pig iron annually.

ArcelorMittal owns the largest mining and metallurgical plant in Ukraine, ArcelorMittal Kryvyi Rih, and a number of small companies, including ArcelorMittal Berislav.

Over the past three years, ArcelorMittal Corporation has provided $1 billion in aid to its Kryvyi Rih mining and metallurgical plant, ArcelorMittal Kryvyi Rih (AMKR, Dnipro region), Mauro Longobardo, CEO of AMKR, said.

According to him, ArcelorMittal Kryvyi Rih’s total charitable assistance since the beginning of the war has amounted to over UAH 710 million.

“Our main task in 2024 was to work despite all the challenges to be able to pay taxes and help communities. We were able to achieve this, in particular, thanks to the support of the parent company. Over the past three years, the group has supported us with more than $1 billion, of which capital investments amounted to $0.3 billion,” the CEO said, as quoted by the press service.

He added that as one of the largest taxpayers, we understand that these funds are used for the country’s defense and to bring the Victory closer.

“But we also understand our responsibility to the city, surrounding communities and our employees. Despite the unprofitable financial results, we did a lot of work to reintegrate veterans who returned to us after serving in the Armed Forces, helped the families of our fallen colleagues, employees affected by enemy attacks, and assisted in the restoration of infrastructure facilities in various communities. We will continue to do everything we can to ensure that Ukraine wins and starts rebuilding,” the CEO emphasized.

According to the press release, in 2024, AMKR allocated more than UAH 60 million to support communities and provide charitable assistance to war-affected people. In 2024, the main areas of the company’s social and charitable activities were to help local communities and war victims. The company focused its efforts on reducing internal costs and optimizing resource consumption, but despite the difficult financial situation, it provided assistance to healthcare and education institutions in Kryvyi Rih and the region.

A significant part of the company’s social assistance is to help the families of employees who died and employees whose homes were destroyed or damaged by hostile shelling: UAH 35.55 million in payments to the families of the deceased, UAH 6 million 406.3 thousand in assistance to the victims of shelling. The company allocated UAH 3.4 million to repair the neurological department of the Kryvyi Rih Central District Hospital of the Novopil Village Council.

More than UAH 1.8 million was allocated to the city’s educational institutions. The main projects include repairing the roof of the Kryvyi Rih Metallurgical Vocational College, manufacturing and installing a fence to equip the educational building No. 3 of the Kryvyi Rih College, and helping to repair classrooms and workshops for three Kryvyi Rih educational institutions: Kryvyi Rih Metallurgy and Machine Building Education Center, Kryvyi Rih Professional Mining and Metallurgical Lyceum and Transport and Metallurgical Lyceum.

In 2024, AMKR continued to provide assistance to communities, allocating about UAH 1 million for their development. The company allocated slag and crushed stone for road filling and repair to restore the infrastructure of districts and rural communities (Metallurgical District Council in the city, Kamyanka village in Kryvyi Rih district to fill the dam, Lozuvata and Sofiyivka communities).

AMKR helped to repair the water supply system in Stepove village of the Grechanopodiv community and provided slag for road repairs in Kherson region. The company also manufactured and installed a monument to the fallen defenders in Arkhangelske village, Beryslav district, Kherson region.

In addition, the company provided 100,000 tons of blast furnace slag to the State Border Guard Service of Ukraine to improve departmental border roads. AMKR also provided assistance in other areas, mostly aimed at working with veterans of the plant and the city and their reintegration into society. The main types of assistance included: helping the Veteran service office to set up a newly created veteran hub; assisting in organizing the charity concert “With Faith in Victory”; organizing a field trip for children with special needs to Kamyanets-Podilsky; and helping the Veterans Union NGO.

In 2024, with the support of Korn Ferry, the company also developed and implemented the project “Return of Veterans to Civilian Life,” which includes the organization of a coordination center for veterans on the basis of the Single Window, the creation of inclusive workplaces with individual work with each veteran, rehabilitation programs for veterans on the basis of the company’s medical center and health insurance, priority provision of vouchers to mobilized and demobilized employees, and preferential meals in the canteens of the AMKR.

“ArcelorMittal Kryvyi Rih is the largest rolled steel producer in Ukraine. It specializes in long products, including rebar and wire rod.

ArcelorMittal owns the largest mining and metallurgical plant in Ukraine, ArcelorMittal Kryvyi Rih, and a number of small companies, including ArcelorMittal Berislav.

ArcelorMittal Kryvyi Rih’s Kryvyi Rih Mining and Metallurgical Plant (AMKR, Dnipro region) intends to extend the previously defined environmental protection measures for two years after the war.

According to the materials available to Interfax-Ukraine, the company intends to obtain permits for emissions of pollutants into the atmosphere from stationary sources – sintering machines No. 1-3 of sinter shop No. 2, extend the deadlines for implementing measures to reduce pollutant emissions and operate generators to be used to provide electricity to consumers in the event of a power outage.

It is specified that the generators to be used during the power outage are not subject to environmental impact assessment and do not belong to the types of activities of facilities that may have a significant impact on the environment.

The plant has completed a complete reconstruction of Sinter Shop No. 2 (SSC-2), namely six sinter machines, to meet the maximum permissible emission standards in accordance with the law. The number of irrigation nozzles was increased at four gas purification units of the sinter plant’s charge preparation department (AC-3), and the dust standard of 50 mg/cubic meter was achieved.

The planned environmental protection measures include the installation of water cannons for dust suppression in the charge material warehouses, improving the efficiency of the existing 23 treatment plants of the charge material preparation department of the sinter plant (AC-3), including their modernization, reconstruction, repair, etc. It is also planned to decommission AC-1 after the pelletizing plant is commissioned.

The plant’s materials list the process equipment for which advanced technological standards have been established, including sinter machines. AMKR undertakes to implement emission reduction measures on this equipment after two years from the date of termination or lifting of martial law in Ukraine.

“ArcelorMittal Kryvyi Rih is the largest rolled steel producer in Ukraine. It specializes in long products, including rebar and wire rod.

ArcelorMittal owns the largest mining and metallurgical plant in Ukraine, ArcelorMittal Kryvyi Rih, and a number of small companies, including ArcelorMittal Beryslav.

ArcelorMittal Kryvyi Rih’s Kryvyi Rih Mining and Metallurgical Plant (AMKR) saved more than UAH 200 million in the period from May 2020 to July 2024 as part of a program to modernize lighting systems.

According to the company’s information in the corporate publication Metallurg, the program is still being implemented.

It was specified that the program has significantly improved lighting in the main premises of ten shops.

According to Alexander Efremov, Head of Energy Management Department, the company spends the most money on natural gas and electricity, the prices for which have risen sharply, out of all the energy resources purchased. He also noted that electricity is used not only to run production equipment but also to illuminate shop buildings and other premises. Thousands of different lighting fixtures with different types of lamps are used to illuminate numerous buildings and structures. Among them are outdated, inefficient and uneconomical incandescent lamps, sodium lamps and others.

“Modern achievements in this area have proven that LED lighting fixtures are many times more powerful and economical: A 10-watt economy lamp gives as much light as a 100-watt incandescent lamp. In addition, in many workshop buildings and structures, the lighting level ranges from 30 to 70 lux, while the standards require at least 200. So the need for changes is urgent,” explained Yefremov.

According to him, the modernization requires significant funds, so the experts decided to use energy service contracts, where the contracted energy company replaces the lighting system at its own expense and then receives money from energy savings together with the enterprise.

“The quality of the services and equipment provided by Ukrainian energy companies was very high. The pilot project of the program started at the end of 2020 in Rolling Shop No. 3. The modernization was completed in May 2021. We took measurements and received at least 200 lux, and the first months of using the new lighting showed the reliability and savings we expected. The next participants in the program were the first ore dressing and crushing plants of the Mining Department. We have achieved considerable savings,” stated the head of the department.

The program continued after the full-scale invasion. The main buildings of a number of shops, as well as ROF-2, SPC-1, BOF Shop, Blooming Shop and other shops, received new powerful, economical lighting. Some units modernized systems at additional facilities. The implementation is ongoing at Sinter Shop 2. Several other shops are next in line.

“We sign a long-term contract with the contractor, and together we measure and record the current level of lighting and electricity consumption. Then our partners completely change the equipment – switches, electrical wires, lamps and fixtures. Then, on a monthly basis, we record energy consumption and calculate the savings compared to pre-modernization costs. During these contract years, the contractor maintains and repairs the equipment,” explained Yefremov.

“ArcelorMittal Kryvyi Rih is the largest rolled steel producer in Ukraine. It specializes in long products, including rebar and wire rod.

ArcelorMittal owns the largest mining and metallurgical plant in Ukraine, ArcelorMittal Kryvyi Rih, and a number of small companies, including ArcelorMittal Berislav.

ArcelorMittal Kryvyi Rih’s Kryvyi Rih Iron and Steel Works (AMKR, Dnipro region) is gradually increasing production by commissioning idle units and overcoming the consequences of Russian aggression.

“We used to operate at 25% of capacity, but now we are gradually increasing production every day. This, in turn, will lead to an increase in jobs and taxes for our city and the Ukrainian economy,” the press service said on Friday.

It is specified that coke oven batteries No. 3-4 are scheduled to be launched from April 21 to 24 inclusive, which will provide raw materials for the increase in blast furnace production.

“We would like to draw the attention of Kryvyi Rih residents to the fact that during the launch of coke oven batteries, there may be a noticeable emission of smoke. We would like to inform you that the smoke is caused by the technological process of the launch, the situation is safe for the residents of the city,” explains AMKR.

As reported earlier, ArcelorMittal Kryvyi Rih increased steel production by 93% in January-March 2024 to 278 thousand tons compared to the same period in 2023. The company produced 245 thousand tons of blast furnace coke compared to 211 thousand tons (up 16%), 403 thousand tons of pig iron compared to 392 thousand tons (up 3%), 278 thousand tons of steel compared to 250 thousand tons (up 11%), and 262 thousand tons of rolled products compared to 230 thousand tons (up 14%).

Production growth compared to the first quarter of 2023 ranged from 50% to 94%, depending on the type of product.

The first quarter of 2024 also reflects gradual progress in the restoration of the plant’s production capacity.

“We plan to continue our production development program, in particular, to approach 50% of our steelmaking capacity in the near future. At the same time, the stability of energy supply remains a significant factor in the successful implementation of our plans,” said Mauro Longobardo, CEO of AMKR, earlier.

“ArcelorMittal Kryvyi Rih is the largest rolled steel producer in Ukraine. It specializes in long products, including rebar and wire rod.

ArcelorMittal owns the largest mining and metallurgical plant in Ukraine, ArcelorMittal Kryvyi Rih, and a number of small companies, including ArcelorMittal Berislav.

In January-March this year, ArcelorMittal Kryvyi Rih Iron and Steel Works (AMKR, Dnipro region) increased steel production by 93% year-on-year to 278 thousand tons.

According to the company, compared to the fourth quarter of last year, iron ore concentrate production amounted to 1.775 million tons versus 1.283 million tons (38% more).

Blast furnace coke production in January-March 2023 amounted to 245 thousand tons compared to 211 thousand tons (up 16%), pig iron – 403 thousand tons compared to 392 thousand tons (up 3%), steel – 278 thousand tons compared to 250 thousand tons (up 11%), rolled products – 262 thousand tons compared to 230 thousand tons (up 14%). Production growth compared to the first quarter of 2023 ranged from 50% to 94%, depending on the type of product.

In March 2024, compared to March 2023, production of iron ore concentrate increased by 52% (from 427 thousand tons to 651 thousand tons), blast furnace coke by 50% (from 56 thousand tons to 84 thousand tons), pig iron by 27% (from 109 thousand tons to 138 thousand tons), steel by 61% (from 77 thousand tons to 124 thousand tons) and rolled products by 57% (from 74 thousand tons to 116 thousand tons). Production volumes also grew year-on-year, with iron ore concentrate up 14%, blast furnace coke up 9%, pig iron up 19%, and steel and rolled products up 61% and 59%, respectively.

These results were achieved despite Russian attacks against energy infrastructure and the resulting power outages, the press release said.

The first quarter of 2024 also reflects gradual progress in restoring the company’s production capacity.

“We plan to continue our production development program, in particular, to approach 50% utilization of our steelmaking capacity in the near future. At the same time, the stability of energy supply remains a significant factor in the successful implementation of our plans,” said Mauro Longobardo, CEO of AMKR.

“ArcelorMittal Kryvyi Rih is the largest rolled steel producer in Ukraine. It specializes in long products, including rebar and wire rod.

ArcelorMittal owns the largest mining and metallurgical plant in Ukraine, ArcelorMittal Kryvyi Rih, and a number of small companies, including ArcelorMittal Berislav.

Mittal Steel Corporation acquired a 93.02% stake in Kryvorizhstal in an open tender on October 24, 2005 for UAH 24.2 billion at a starting price of UAH 10 billion, after which the plant was renamed Mittal Steel Kryvyi Rih and later ArcelorMittal Kryvyi Rih.