PrJSC Centravis Production Ukraine (Centravis Production Ukraine), which is part of the holding Centravis Ltd., operates two lines for the production of pipes under shelling in Nikopol, where the company’s assets are located.

“Centravis production continues to operate. Hot and cold shops continue to work in 2 shifts. All key equipment is working. Production is provided with blanks and all necessary materials,” said Artem Atanasov, Sales Director (Chief Sales Officer, CSO), in a letter to customers.

At the same time, he noted that the logistics team of the enterprise is actively working and is constantly looking for the best and safest ways to deliver finished products.

Sales offices around the world in Essen, Milan, Krakow, Lugano, Houston and Dubai are open, the top manager emphasized.

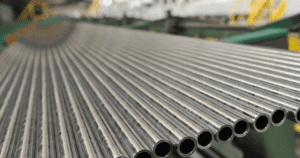

Centravis is one of the world’s largest manufacturers of seamless stainless steel pipes, founded in 2000. Its production facilities are located in Nikopol (Dnepropetrovsk region). Included in the top 10 global players, supplies pipes to more than 70 countries from different regions, in particular to Thyssenkrupp, Buhlmann, BMW, Alstom, Linde, Samsung, Volkswagen.

Before the Russian aggression, more than 1,400 people worked at the enterprise.

Holding Centravis Ltd. was created on the basis of CJSC “Nikopol Stainless Pipe Plant”, service and trading companies LLC “Production and Commercial Enterprise “UVIS”. Its shareholders are members of the Atanasov family.

Owned by Centravis Ltd. 100% of the shares of PJSC “Centravis Production Ukraine” is located.

PrJSC Centravis Production Ukraine, which is part of the holding Centravis Ltd., continues the production process and launched the second pipe production line. “Centravis continues to work. Since Monday, the hot and cold shops of the enterprise have been working in two shifts. All key equipment is working,” Chief Sales Officer (CSO) Artem Atanasov said in a letter to customers on Friday.

At the same time, the company also continues to work on key resource-saving projects.

“Production is provided with pipe billets and all necessary materials,” he said in the letter.

He added that the logistics team is actively working to safely deliver products to customers. Sales offices around the world in Essen, Milan, Krakow, Lugano, Houston and Dubai are open, financial and administrative customer support departments also continue to work.

Centravis is one of the world’s largest manufacturers of seamless stainless steel pipes, founded in 2000. Its production facilities are located in Nikopol (Dnipropetrovsk region). It is included in the top 10 global players, supplies pipes to more than 70 countries from different regions, in particular to Thyssenkrupp, Buhlmann, BMW, Alstom, Linde, Samsung, Volkswagen.

PJSC Centravis Production Ukraine (Centravis Production Ukraine), part of the Centravis Ltd. holding, has resumed the production process after it was suspended last week due to shelling by Russian invaders of the city of Nikopol, Dnepropetrovsk region, where the company’s assets are located.

“Last week, we suspended production due to the tense situation in Nikopol. The shelling of Nikopol, fortunately, stopped. The employees of Centravis were not injured. The production equipment was not damaged. Today, the company’s team decided to resume production,” said the director of Chief Sales Officer, CSO Artem Atanasov in a letter to clients on Monday.

According to him, the production works in one shift.

In turn, sales managers continue to take orders.

“We are observing all security measures,” Atanasov stressed.

As reported, Centravis last week continued to ship products despite the suspension of production. At the same time, the supply of blanks to the enterprise was stable.

Centravis is one of the world’s largest manufacturers of seamless stainless steel pipes, founded in 2000. Its production facilities are located in Nikopol (Dnepropetrovsk region). Included in the top 10 global players, supplies pipes to more than 70 countries from different regions, in particular to Thyssenkrupp, Buhlmann, BMW, Alstom, Linde, Samsung, Volkswagen.

Before the Russian aggression, more than 1,400 people worked at the enterprise.

Holding Centravis Ltd. was created on the basis of CJSC “Nikopol Stainless Pipe Plant”, service and trading companies LLC “Production and Commercial Enterprise “UVIS”. Its shareholders are members of the Atanasov family.

Owned by Centravis Ltd. 100% of the shares of PJSC “Centravis Production Ukraine” is located.

PJSC Centravis Production Ukraine (Centravis Production Ukraine), part of the holding Centravis Ltd., suspended the production process last week due to shelling by Russian invaders of the city of Nikopol, Dnepropetrovsk region, where the company’s assets are located.

“The Russians continue their terror against the civilian population of Ukraine, the shelling of civilian infrastructure. Nikopol was no exception. The employees of Centravis were not injured. The production equipment was not damaged,” Chief Sales Officer (CSO) Artem Atanasov said in a letter to customers in Friday.

According to him, at the time of the escalation, the administration of Centravis took additional security measures to protect employees and their families.

“We continue to ship products. The main production was temporarily stopped this week, but we plan to restart it on Monday, July 25,” the sales director stated.

At the same time, he noted that the supply of blanks to the enterprise is stable. “We continue to accept orders, there is an opportunity to place orders for September and beyond,” Atanasov said.

He added that the logistics team is actively working and constantly looking for better and safer ways to deliver finished products. Sales offices around the world in Essen, Milan, Krakow, Lugano, Houston and Dubai are open, financial and administrative customer support departments also continue to work.

Centravis is one of the world’s largest manufacturers of seamless stainless steel pipes, founded in 2000. Its production facilities are located in Nikopol (Dnepropetrovsk region). Included in the top 10 global players, supplies pipes to more than 70 countries from different regions, in particular to Thyssenkrupp, Buhlmann, BMW, Alstom, Linde, Samsung, Volkswagen.

Before the Russian aggression, more than 1,400 people worked at the enterprise.

Holding Centravis Ltd. was created on the basis of CJSC “Nikopol Stainless Pipe Plant”, service and trading companies LLC “Production and Commercial Enterprise “UVIS”. Its shareholders are members of the Atanasov family.

Owned by Centravis Ltd. 100% of the shares of PJSC “Centravis Production Ukraine” is located.

Dniprospetsstal electrometallurgical plant (Zaporizhia) has begun a gradual launch of production, including for the purpose of supplying stainless steel to PrJSC Centravis Production Ukraine, which is part of holding Centravis Ltd.

Chief Sales Officer (CSO) Artem Atanasov said in a letter to Centravis customers that the company is experiencing a positive trend in the supply of pipe billets for production.

“Dniprospetsstal, our main billet supplier, is gradually launching production, and in the near future we expect stable supply volumes,” Atanasov stated.

According to him, Centravis is operating normally, both in hot and cold shops. At the same time, in the hot production, all actual performance indicators are higher than planned, in the cold shop, several lines operate at the level of stable operation before the war.

The sales director recalled that the plant began to offer products and take orders.

“Your continued support (from customers) is extremely important to us at this stage. Buying pipes from Centravis means that you support the restart of the Ukrainian economy, which is now more important than ever. Our logistics team is actively working and constantly looking for better and safer ways for delivery of finished products,” Atanasov emphasized, adding that the company is actively preparing for participation in the Tube&Wire exhibition, which will be held in Dusseldorf on June 20-24.

Centravis is one of the world’s largest manufacturers of seamless stainless steel pipes, founded in 2000. Its production facilities are located in Nikopol (Dnipropetrovsk region). It is included in the top 10 world players. Before the Russian aggression, more than 1,400 people worked at the enterprise.