In 2025, Kametstal Plant, part of Metinvest Mining and Metallurgical Group (Kamensk, Dnipropetrovsk region), carried out a series of important equipment repairs and expanded its product range by seven items.

According to the company, in 2025, despite the obstacles posed by the war, the company continued to operate, develop and support the economic strength of the region and Ukraine.

Thus, despite logistical difficulties and energy instability, Kametstal implemented the most ambitious capital repair programme of the war years, the most important of which were the overhaul of blast furnace No. 9, a complex of overhauls of the main equipment of both converters, the installation of furnace ladle No. 1, MBLZ-1, and major repairs of the section rolling and pipe mill.

It is noted that Kametstal expanded its product range by seven items and once again became the leader among Metinvest’s enterprises. The plant was the first among the group’s enterprises to commission a gas piston power plant to generate its own electricity. This made it possible to increase the energy security of the main production equipment during wartime.

In the converter shop, continuous casting machine (CCM) No. 1 was reconstructed: important electrical equipment, automated control systems, and key equipment of the machine’s drawing and straightening devices were upgraded in two stages. The electrical equipment of CCM No. 2 was also modernised.

In addition, the construction of new above-ground high- and medium-pressure water pipes to support the technological processes of the converter and lime-burning shops in particular was completed and put into operation.

In 2025, the company invested almost UAH 43 million in improving working conditions at the enterprise.

Kametstal is part of the Metinvest Group.

The Zaporizhstal Iron and Steel Works in Zaporizhia allocated UAH 370 million for a complex of major repairs of key production units.

According to a press release issued by the plant on Tuesday, the company is continuing to implement its annual capital investment program to maintain production capacity and environmental protection equipment. The plant has carried out a major overhaul of its main production units in the blast furnace, open-hearth furnace, and hot rolling mill departments, with a total budget of UAH 370 million.

“The domestic mining and metallurgical complex is one of the export-oriented sectors of the Ukrainian economy that has lost the most during the war. We are focusing on survival, because it is the preserved production that will become the basis for future modernization and development projects. Repairs and proper maintenance of production complexes are an important contribution to ensuring the stable operation of Zaporizhstal today and in the future,” said Taras Shevchenko, acting CEO of the metallurgical plant.

According to him, the plant has carried out a series of repairs in the main production units of the enterprise: blast furnace (BF) No. 3 and its gas cleaning system, aspiration of the casting yard and bunker trestle in the blast furnace shop, a two-tank steelmaking unit and its gas cleaning system in the open-hearth shop, the 1150 slab mill and the BTLS-1680 mill, as well as shears and clamp cranes in the hot rolling shop. The work continued around the clock, with more than 400 specialists involved in the repairs: employees of the engineering services and production departments of Zaporizhstal, specialists from Zaporizhogneupor, Kametstal, and contracting organizations.

It is specified that thanks to the overhaul, DP-3, in particular, will ensure high efficiency of technological air cleaning from dust at the level of 20 mg/cubic meter.

As part of the repair of the two-tank steelmaking unit, the main vault and working space of the furnace were refired. For this purpose, Zaporizhogneupor supplied more than 800 tons of refractory fireclay and periclase-chromite products.

At the slabbing-1150 mill, repairs were carried out on the universal cage and its electric drive, roller tables, pressure units of horizontal and vertical rolls, turntable units with platform replacement, overhaul of the mill’s electrical and power equipment, repair of control panels, etc. At the BTLS-1680 mill, specialists inspected and upgraded the unit’s components.

It is also noted that the overhauls were aimed at improving the reliability and efficiency of the equipment, reducing product defects and energy losses. It should be noted that this year Zaporizhstal will also carry out a complex of major repairs of key units of the combined heat and power plant – boiler unit No. 5, turbine generator No. 1, and turbo compressor unit No. 7. The plant has allocated about UAH 75 million in investments for these purposes. Overall, despite the difficult economic situation, the capital investment budget for 2025 will exceed UAH 1 billion.

Zaporizhstal is one of Ukraine’s largest industrial enterprises, whose products are in high demand among consumers both in the domestic market and in many countries around the world.

Zaporizhstal is a joint venture of the Metinvest Group, whose main shareholders are System Capital Management (71.24%) and Smart Steel Limited (23.76%). Metinvest Holding LLC is the managing company of the Metinvest Group.

The Kametstal plant of the Metinvest mining and metallurgical group (Kamensk, Dnipropetrovsk region) has begun a series of major repairs of its main rolling equipment under the 2025 program.

According to the company, the first to undergo major renovation was the pipe mill (PM), which produces SVP-27 mine props and large-diameter grinding balls.

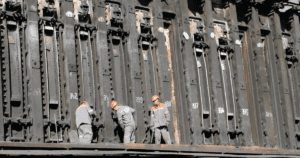

It is specified that at the main stage of the overhaul, the efforts of specialists from the metallurgical equipment repair shop and the equipment repair shop are focused on work to upgrade the power, in particular electrical and mechanical, equipment of key large-scale sections, which can only be repaired during a complete and prolonged shutdown of the mill.

Thus, in the rolling mill section, the manipulator lines are being upgraded, the electrical panels of the heating furnaces and the guide bushings of the 900 mill are being replaced. A thorough inspection of the units is being carried out, with all necessary repair operations being performed on the first, second, and third 750 mills. On the roller table field of the rolling mill, to ensure the stability of the rolling movement, the bearings on the rollers and the rollers themselves, worn out due to prolonged operation, are being replaced.

Another important task is to replace a section of the water supply pipeline, which will create an additional backup supply for uninterrupted water supply for the technological needs of the pipe preparation section.

Rolling mill employees, in turn, are cleaning the hydraulic tunnel, removing accumulated scale from the communication structure for technical water drainage.

“This is an important overhaul for the shop and the entire enterprise, aimed primarily at improving the reliability of the pipe mill equipment, which produces strategic SVP-27 profile rolled products for miners. The section is also an important link in the production of billets for large-diameter grinding balls, a product in high demand that is produced on the shop’s ball rolling mills,” the company said in a statement.

Kametstal is part of the Metinvest Group.

PrJSC Dniprovsky Metallurgical Plant (DMZ, formerly Evraz-DMZ), a member of DCH Steel of the DCH group of businessman Oleksandr Yaroslavsky, has completed the first stage of overhaul of coke oven battery No. 4, which will reduce emissions of air pollutants.

According to the company’s press release on Thursday, the total investment is about UAH 170 million.

As part of the investment project, 20 coking chambers were repaired at the DMZ coke-chemical site. Repaired furnaces do not lose coke oven gas – all of it goes for treatment. Due to the sealing of the refractory masonry, the elimination of leaks into the heating system from the coking chambers and more complete combustion of gas in verticals, emissions of pollutants will decrease.

The press service also said that the excess of coke oven gas, which may be formed during the commissioning period, will be sent to the afterburner, the work of which is fully consistent with the technological process. The repair of the rest of the coking chambers will continue at the operating battery, and it is planned to complete it by the end of the year.

“DMZ is systematically engaged in the modernization of fixed assets at the coke-chemical site. In addition to the overhaul of coke oven battery No. 4, this year, ceramic surfacing is being carried out at coke oven battery No. 1 and coke oven battery No. 2 with sealing of heating walls. In general, this will increase the efficiency of the furnaces and significantly reduce the burden on the environment,” Director General of the DMZ Vitaliy Bash said.

At the same time, it is recalled that since 2016, DMZ has invested UAH 475 million in environmental programs. During this time, the company has reduced air emissions by almost 25%. Now the enterprise has an investment program in the amount of $400 million, aimed at modernizing production facilities and reducing the burden on the environment.

DMZ specializes in the production of steel, cast iron, rolled products and products from them.

The European banks will provide EUR 900 million for overhaul of Kyiv-Odesa highway in Ukraine, said acting Chief of Ukravtodor Ukrainian Automobile Roads Agency Slawomir Nowak. “We managed to complete negotiations with the European banks, with EIB and BRD, and Ukraine will be granted the next 900 million euros for the overhaul of Kyiv-Odesa and assignment of an autobahn category to this road. From the next building season, they must begin repairs,” website of Hromadske media quotes Nowak as saying.

According to him, overhaul of Kyiv-Odesa highway will begin in 2020 and the highway is to become autoban after reconstruction. Three or four years needed for overhaul of this highway, Nowak said.

As reported, Nowak handed in resignation to Prime Minister of Ukraine Oleksiy Honcharuk following the termination of his three-year tenure.