Lviv IT-company SoftServe plans to invest over $100 million in the construction of a creative office campus on the site of Lviv penal colony No. 48 acquired for UAH 377.5 million at a privatization auction.

According to a SoftServe press release on the Business Wire portal, construction will begin in 2022 and it will take about five years. An international architectural bureau will be involved in the work on the project.

“The new campus will not only breathe new life into the whole district of Lviv, but will also continue the development of the city as a major educational and technological hub in Ukraine and in the world,” the co-founder and member of the Board of Directors of SoftServe, Oleh Denys, said.

According to the project, the campus will house SoftServe offices, as well as the company’s corporate university, conference rooms and exhibition grounds, a school and a kindergarten, and apartments.

As reported, SoftServe acquired Lviv penal colony No. 48 on a 10.7 hectare plot for UAH 377.5 million at a privatization auction held on June 3.

SoftServe specializes in software production, development services, quality control and support of information systems and business solutions. To date, about 10,000 employees of the company work in 38 offices. The main offices of the company are located in Lviv and Austin (Texas, the United States). The company’s development centers are located in Lviv, Kyiv, Dnipro, Kharkiv, Rivne, Ivano-Frankivsk, Chernyvtsi, Sofia (Bulgaria) and Wroclaw, Bialystok, Gliwice and Warsaw (Poland).

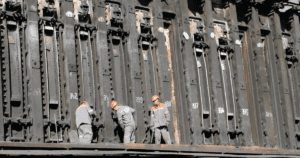

PrJSC Dniprovsky Metallurgical Plant (DMZ, formerly Evraz-DMZ), a member of DCH Steel of the DCH group of businessman Oleksandr Yaroslavsky, has completed the first stage of overhaul of coke oven battery No. 4, which will reduce emissions of air pollutants.

According to the company’s press release on Thursday, the total investment is about UAH 170 million.

As part of the investment project, 20 coking chambers were repaired at the DMZ coke-chemical site. Repaired furnaces do not lose coke oven gas – all of it goes for treatment. Due to the sealing of the refractory masonry, the elimination of leaks into the heating system from the coking chambers and more complete combustion of gas in verticals, emissions of pollutants will decrease.

The press service also said that the excess of coke oven gas, which may be formed during the commissioning period, will be sent to the afterburner, the work of which is fully consistent with the technological process. The repair of the rest of the coking chambers will continue at the operating battery, and it is planned to complete it by the end of the year.

“DMZ is systematically engaged in the modernization of fixed assets at the coke-chemical site. In addition to the overhaul of coke oven battery No. 4, this year, ceramic surfacing is being carried out at coke oven battery No. 1 and coke oven battery No. 2 with sealing of heating walls. In general, this will increase the efficiency of the furnaces and significantly reduce the burden on the environment,” Director General of the DMZ Vitaliy Bash said.

At the same time, it is recalled that since 2016, DMZ has invested UAH 475 million in environmental programs. During this time, the company has reduced air emissions by almost 25%. Now the enterprise has an investment program in the amount of $400 million, aimed at modernizing production facilities and reducing the burden on the environment.

DMZ specializes in the production of steel, cast iron, rolled products and products from them.

Synevo laboratory, part of the Swedish medical holding Medicover, has invested EUR500,000 in the launch of a new laboratory with a capacity of more than 400,000 tests in Kherson.

According to a press release from Synevo, the new laboratory will be opened on the basis of the Taurt Medical center and will serve both the clients of the clinic and the orders of Synevo’s clients in Kherson region.

In the near future the laboratory plans to fulfill orders for Synevo clients from Mykolaiv, Zaporizhia, Dnipropetrovsk and Donetsk regions.

The laboratory plans to carry out general clinical, biochemical, immunochemical, hematological and cytomorphological studies.

The Synevo laboratory in Kherson is the eighth operating laboratory of the company in Ukraine. Synevo laboratories also operate in Kyiv, Odesa, Kharkiv, Lviv, Vinnytsia, Dnipro, Chernivtsi.

Similarly to other Synevo laboratories, the laboratory in Kherson complies with international standards for laboratory diagnostics and is equipped with automated equipment from leading manufacturers from the United States, Japan, Switzerland, Germany (Zeiss, Roche, Sysmex and others), which performs all stages of research in an automatic mode without human intervention.

Synevo is the largest network of laboratories in Ukraine, part of the Swedish medical holding Medicover. The Synevo network includes 320 laboratory centers operating in 125 settlements of Ukraine, as well as eight laboratories in which more than 1,000 types of tests are performed.

The Dobrobut medical network invested more than UAH 300 million in equipment in 2020, plans to increase the volume of investments in 2021, chief operating officer of the network Vadym Shekman has said.

“We want our doctors to work on high-quality equipment. In 2020 we invested more than UAH 300 million in equipment, in 2021, I think, there will be even more,” he said in an interview with Interfax-Ukraine.

He noted that the shareholders of the company decided not to distribute dividends.

“The company does not withdraw money, we invest all the money that Dobrobut earns and additional investments in development. Most likely, we will not slow down this pace in the next 3-4 years,” he said.

Metinvest, an international vertically integrated mining and metallurgical group of companies, is launching a large-scale project for the construction of a new workshop for the production of cold-rolled steel, galvanized and painted coils at Illich Metallurgical Plant (Donetsk region). According to a company press release, the group signed a contract for the supply of equipment with the world’s leading supplier of metallurgical technologies, Italy’s Danieli, on June 10. The total investment in the project will exceed $1 billion.

At the same time, it is specified that it is planned to build a cold rolling shop at Illich steel mill, which will consist of a continuous cold rolling mill combined with a pickling line, as well as three modern lines for applying zinc, aluminum-zinc and polymer coatings. At the first stage, investments in the project will exceed $800 million.

For the construction of the complex, Metinvest will attract a large foreign contractor with experience of participation in similar projects.

It is planned that in 2025, after the completion of the first stage of the project, the mill will produce about 1.2 million tonnes of highly competitive cold-rolled and galvanized steel, as well as color-coated steel per year. At the same time, the capacity for the production of cold-rolled coils will amount to more than 400,000 tonnes, galvanized coils – over 60,000 tonnes and polymer-coated coils – more than 140,000 tonnes.

Yuriy Ryzhenkov, the Director General of Metinvest, noted that the construction of a cold rolling mill is the company’s most ambitious project for the next five years.

“This is a logical continuation of the program of modernization of rolled steel production at Illich steel plant. The entire new technological chain, including a modern continuous casting machine, a reconstructed 1700 mill and a new cold rolling shop, will allow Metinvest to achieve world-class product quality at all stages of production – from semi-finished products to coated rolled products. The production of premium high-tech goods, the use of advanced technologies, environmental friendliness and the creation of new jobs for qualified specialists – all this makes the project significant for Mariupol, for the industry, and for the whole country,” the top manager said.

Eurohold Bulgaria, one of the leading independent financial and insurance groups in South-Eastern Europe, has raised $31 million from the investment fund Global Emerging Markets Group (GEM, Luxembourg), according to a press release from Euroins Ukraine (Kyiv).

According to him, the parties have already signed a commitment agreement. The investment was provided on the basis of equity financing through the purchase of shares in the Bulgarian holding.

The raised funds will be used by Eurohold to acquire the companies of CEZ Group in Bulgaria – one of the largest exporters of electricity in Eastern Europe, as well as to develop its insurance business. The long-term strategic goal of Eurohold is to become one of the leading independent financial service providers and energy market operators in Southeast Europe.

“We are pleased that GEM has decided to invest in our holding and support our investment strategy. The agreement with GEM is a sign of confidence in the quality of management and the chosen vector of development of our company,” Vasil Stefanov, the head of M&A department at Eurohold, said.

As reported, on January 19, the Bulgarian Energy and Water Regulatory Commission issued a permit to the financial and insurance holding Eurohold Bulgaria to purchase seven Bulgarian subsidiaries of CEZ Group.

GEM investment fund, Luxembourg, was founded in 1991 and manages assets in the amount of $3.4 billion. It specializes in investment instruments for emerging markets. To date, the fund has over 400 transactions in 70 countries around the world. The fund’s offices operate in New York, Los Angeles, Paris, Nassau (the Bahamas).

Eurohold Bulgaria, Sofia, was founded in 1996 and is one of the largest independent financial groups in the region of Central, Eastern and South-Eastern Europe. Eurohold Bulgaria shares are listed on the Warsaw Stock Exchange and the Bulgarian Stock Exchange.

Insurance is the largest segment in the portfolio of activities and the main source of income for Eurohold Bulgaria. Euroins Insurance Group (EIG), a member of the holding, is consolidating its operations in the regional insurance markets. The group operates in 11 countries and has subsidiaries in Bulgaria, Ukraine, Romania, North Macedonia, Georgia, Russia and Belarus. EIG has over 4 million customers and over 3,000 employees.

Eurohold’s business in Ukraine is represented by two insurance companies: Euroins Ukraine and European Travel Insurance.