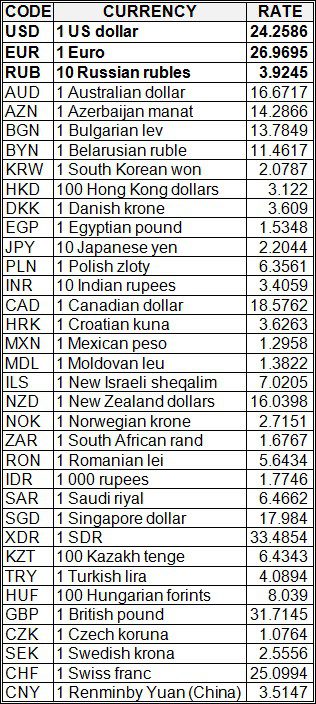

National bank of Ukraine’s official rates as of 22/01/20

Source: National Bank of Ukraine

Odesa Port-Side Chemical Plant, which in recent years during the crisis has been working mainly on tolling, in 2019 increased production of carbamide by 82.1%, to 324,600 tonnes, but reduced production of ammonia by 78.7%, to 29,900 tonnes.

“Last year, 2.549 million tonnes of ammonia were exported, of which 18,600 tonnes of own production, in particular 352,300 tonnes of carbamide, of which 288,500 tonnes of own production,” the company reported.

According to the report, 76,800 tonnes of ammonia were shipped to domestic consumers, of which 3,400 tonnes of domestic production, as well as 3,600 tonnes of carbamide.

In accordance with the plant’s report for 2018, some 2.170 million tonnes of ammonia and 178,300 tonnes of carbamide were handled that year.

Odesa Port-Side Chemical Plant manufactures chemical products, as well as transports chemical products to maritime transport. The state, represented by the State Property Fund, owns 99.5667% of the plant’s shares, while 0.0021% is owned by Concorde Capital LLC, other individual shareholders hold 0.4312%.

Ukraine in January-December 2019 exported 7,190 tonnes of cheese, which is 13.8% less than in 2018.

According to the State Customs Service, in monetary terms exports amounted to $26.88 million, which is 12.7% less than in 2018.

At the same time, cheese imports in 2019 increased by 1.7 times, to 23,720 tonnes. In monetary terms, imports increased by 1.6 times compared to 2018, to $108.87 million.

Last year, export of butter from Ukraine decreased by 1.7 times, to 18,280 tonnes, in money terms also by 1.7 times, to $77.1 million. According to the State Customs Service, import of this product increased by 3.1 times, to 3,410 tonnes, in money terms by 2.2 times, to $16.46 million.

In addition, export of milk and cream (condensed) in 2019 rose by 0.9%, to 35,810 tonnes. In January-December 2019, Ukraine supplied condensed milk and cream for a total of $76.22 million (29.1% more compared to 2018). Imports of this group of goods grew by 8.8%, to 2,560 tonnes, in monetary terms by 1.2%, to $5.78 million.

Ukraine in January-December 2019 increased export of poultry by 26%, to 414,490 tonnes, the State Customs Service has reported. According to its report, in monetary terms exports of these products increased by 14.2%, to $578.63 million. In 2019, import of poultry and offal increased by 0.6% and amounted to 131,180 tonnes, in monetary terms by 1.2%, to $52.53 million.

In addition, according to the agency, pork exports in January-December 2019 amounted to 2,260 tonnes, which is 28.6% more than in 2018. These products were delivered for a total of $5.27 million (39.6% more).

Pork imports to Ukraine last year decreased by 18.8%, to 23,190 tonnes. Pork was imported to the country for $44.23 million, which is 14.8% less than the figure for 2018.

The Ministry of Energy and Environment Protection is creating Ukrvuhillia state-owned enterprise. Corresponding order No. 13 of January 14, 2020 was posted on the website of the department. The document also approves the charter of the enterprise, and obliges the HR department to take measures regarding the appointment of the head of the enterprise.

The ministry said the decision to create Ukrvuhillia was made with the aim of eliminating the shortcomings of the current system of selling coal mined by state-owned coal mining enterprises, conducting a unified state policy regarding the extraction, processing and sale of coal, optimizing the structure of the procurement market, in particular imports, and creating a single platform for a rapid response to the problems of the coal industry.

The main idea of creating the enterprise is to ensure the proper and transparent functioning of the coal market, to protect Ukrainian producers from the influence of uncontrolled imports, as well as to sustainably meet the needs of domestic consumers in scarce grades of coal.

Between October 14, 2018 and October 14, 2019, representatives of nationalist and ultra-right organizations committed 137 acts of violence or attacks against property, journalists, politicians, and activists, said sociologist Oksana Dutchak, who helped with the monitoring project, named “Confrontations and Ultra-Right Violence.” sociologist. “From October 14, 2018 to October 14, 2019, 137 cases were recorded. Of these, 48 is a confrontation, 89 is ultra-right-wing violence directed against people or property,” she said during a press conference at the Interfax-Ukraine news agency on Monday.

The monitoring was carried out by the public organization Institute Republiсa with the support of the Rosa Luxemburg Foundation in Ukraine. It was based on materials on acts of violence or confrontation by ultra-right organizations and movements, information about which was published in the media and social networks.

“Over the indicated period, the largest number of acts of violence and confrontation were committed by representatives of the C14 and National Corps organizations. With the participation of C14, 40 cases were recorded, among which 25 violent attacks, 10 of them against people. The National Corps was involved in 30 episodes, 21 – of a violent nature, 15 of them against people,” said the organizer of the monitoring.

According to the monitoring results, the victims of violent actions by nationalists were most often feminist or LGBT activists, politicians and political parties, representatives of state or law enforcement agencies, as well as journalists.

Authors of the study said they think that Ukraine has a systemic problem with far-right violence, which is generated by inaction, and sometimes indulgence of the law enforcement system. They demand law-enforcement agencies conduct a thorough investigation of hate violence, as well as guarantee the rights of citizens to peaceful assembly, freedom of speech and security.